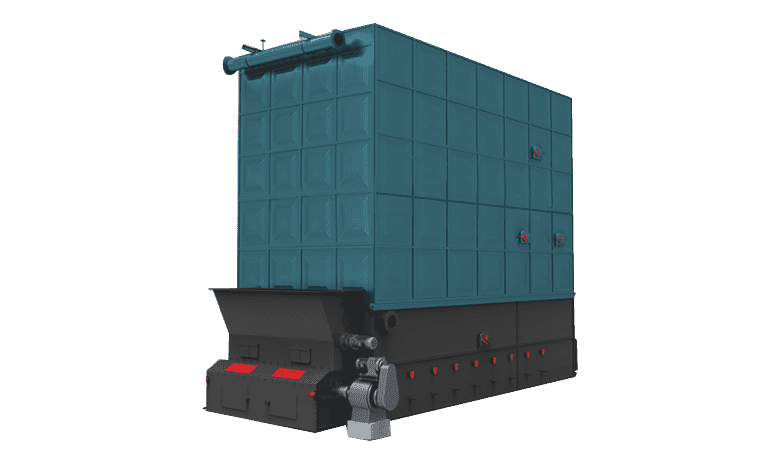

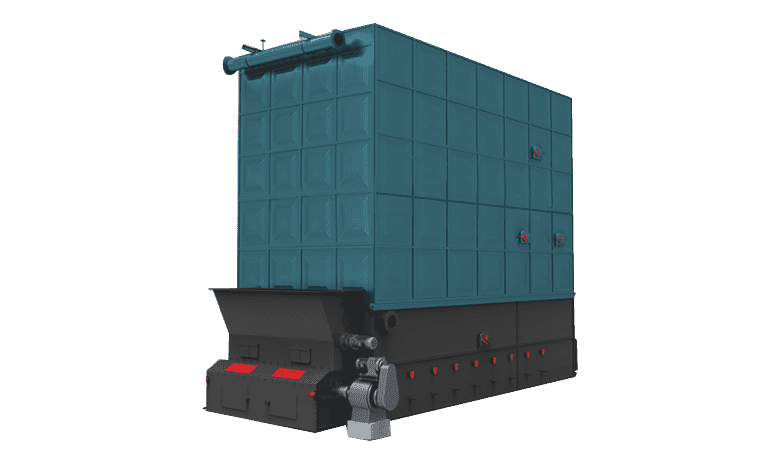

YLW Biomass Fired Thermal Oil Boiler

Capacity: 1.4-30MW (1.2-25 Million Kcal)

Applicable Fuels: Biomass, Coal, Solid fuels, etc.

Applicable Fuels: Biomass, Coal, Solid fuels, etc.

![]()

Application Industries: Petroleum, Chemical, Pharmaceutical,etc.

The YLW biomass fired thermal oil boiler is a horizontal chain grate assembled boiler, featuring multi-loop coil design and customized grate for high combustion efficiency. With flexible environmental configurations and waste heat recovery systems, it perfectly meets your customized requirements.

For more information about this boiler model, please contact us !

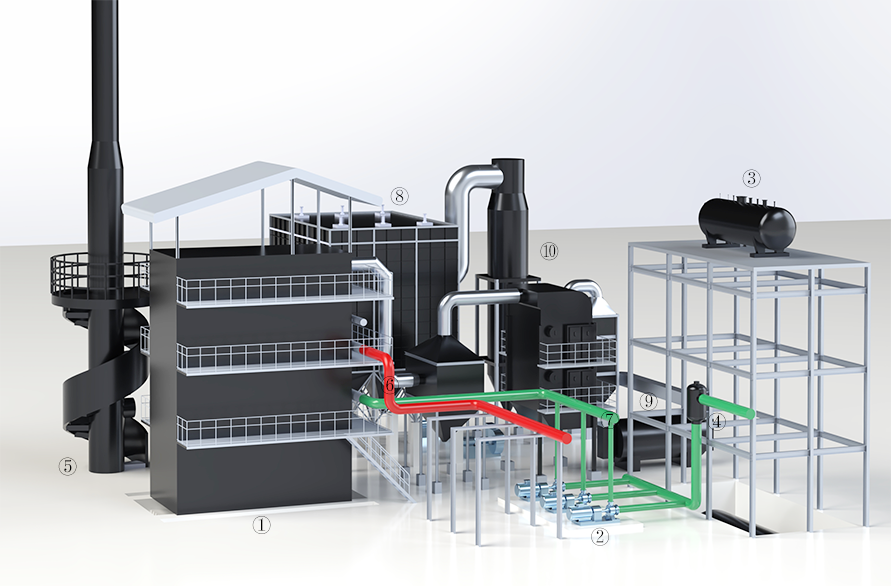

Boiler Core Advantage "Maze-path" Multi-loop Coil Design - Forces flue gas through extended winding passages, significantly increasing heat-absorbing surface area and contact duration. |  | Environmental Protection System Advantage The flexible and adaptable environmental configurations allow customized combinations of dust removal, desulfurization and denitrification facilities at the boiler tail section to comply with diverse regional environmental requirements. |

Waste Heat Recovery Advantage The flexible and adaptable environmental configurations allow customized combinations of dust removal, desulfurization and denitrification facilities at the boiler tail section to comply with diverse regional environmental requirements. |

Wide Fuel Adaptability Suitable for bituminous coal, anthracite coal, various biomass pellets, wood chips and other fuels. | |

High-Efficiency Combustion System The boiler grate size can be custom-tailored to different coal types. This enables thorough mixing of coal, air and heat for complete combustion, improving thermal efficiency while ensuring stable biomass burning operation without flameout, resulting in more reliable boiler performance. |

Modular Transport & Installation The boiler adopts a "split-type transport" design, enabling fast, economical and stable delivery and installation without being restricted by road width/height limitations. After the boiler components are positioned on site, simply connect the pipelines, valves and control circuits to commence operation. |

| ① Boiler body ③ High-level oil storage tank ④ Separator ⑤ Chimney ⑥ Oil pipe ⑧ Environmental Protection Equipment ⑨ Low-level oil storage tank ⑩ Waste heat recovery system |

| Model | YLW-1400S | YLW-1800S | YLW-2400S | YLW-2800S | YLW-3500S | YLW-4200S | YLW-4600S | |

| Rated thermal power | MW | 1.4 | 1.8 | 2.4 | 2.8 | 3.5 | 4.2 | 4.6 |

| x10⁴ kal/h | 120 | 160 | 160 | 240 | 240 | 360 | 400 | |

| Rated outlet temperature | (℃) | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| Rated working pressure | (MPA) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Heat Efficiency | (≥%) | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 |

| System installed capacity | (KW) | 55 | 63 | 76 | 86 | 105 | 125 | 155 |

| Min. transport dimension | Length(MM) | 5000 | 5600 | 6500 | 6500 | 7500 | 7400 | 8000 |

| Width(MM) | 2250 | 2250 | 2500 | 2550 | 2550 | 2870 | 2820 | |

| Height(MM) | 2450 | 2750 | 2800 | 3200 | 3200 | 3300 | 3350 | |

| Max. transportation weight | (KG) | 11000 | 12700 | 13500 | 14500 | 16500 | 25500 | 29000 |

| Model | YLW-6000S | YLW-7000S | YLW-8200S | YLW-9400S | YLW-10500S | YLW-12000S | YLW-14000S | |

| Rated thermal power | MW | 6 | 7 | 8.2 | 9.4 | 1.5 | 12 | 14 |

| x10⁴ kal/h | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | |

| Rated outlet temperature | (℃) | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| Rated working pressure | (MPA) | 1 | 1 | 1 | 10 | 1 | 1 | 1 |

| Heat Efficiency | (≥%) | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 | ≥80 |

| System installed capacity | (KW) | 170 | 193 | 150 | 160 | 160 | 260 | 320 |

| Min. transport dimension | Length(MM) | 8320 | 9000 | 9760 | 9760 | 10500 | 11200 | 10500 |

| Width(MM) | 3330 | 3330 | 3270 | 3500 | 3500 | 3560 | 4000 | |

| Height(MM) | 3250 | 3350 | 4010 | 4010 | 4010 | 4010 | 3500 | |

| Max. transportation weight | (KG) | 33500 | 36000 | 35000 | 24800 | 25000 | 27500 | 31000 |

Leave your email and we’ll send you tailored boiler solutions, case studies, and pricing info within 24h.