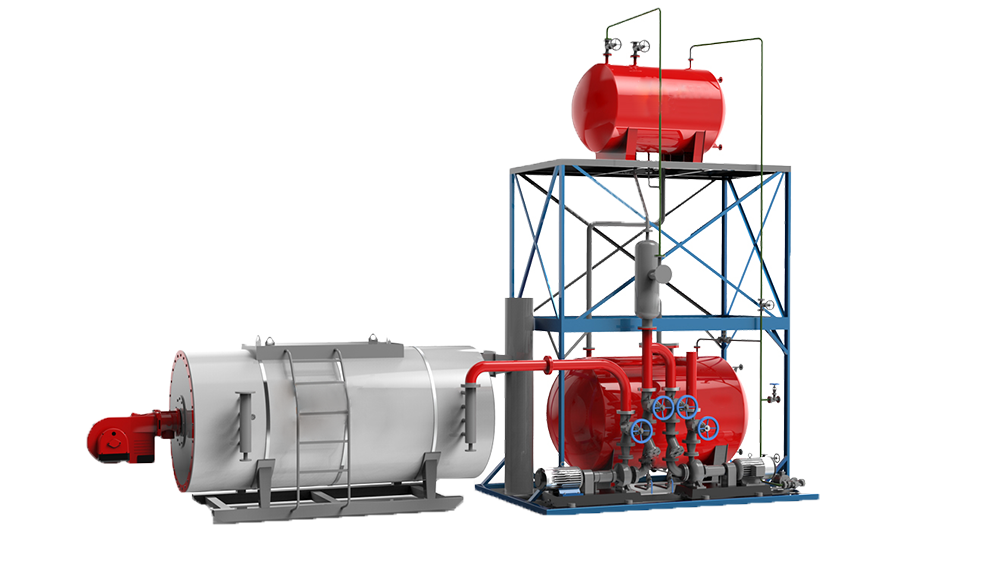

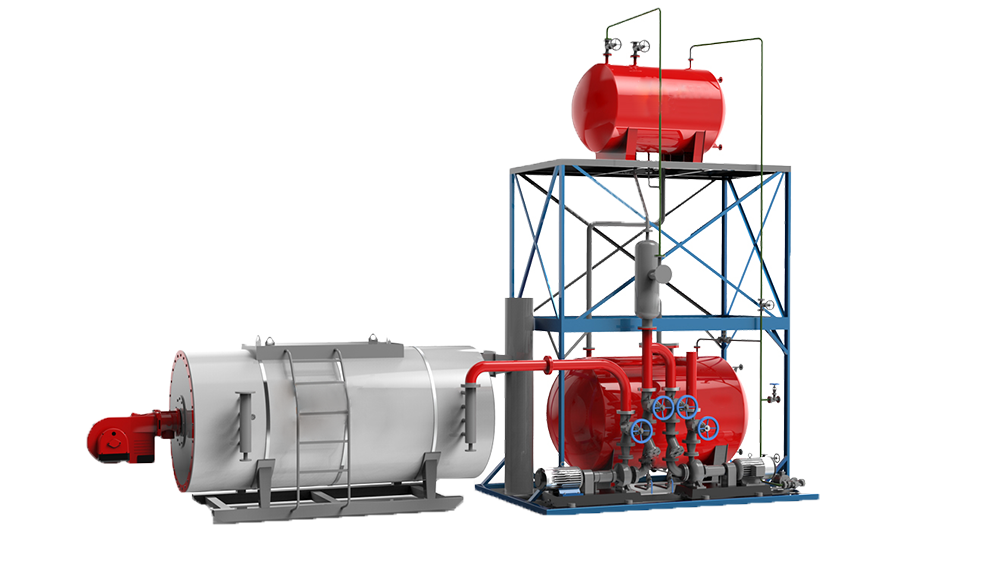

YQ(Y)W Gas/Oil Fired Horizontal Thermal Oil Boiler

Capacity: 1400-14000KW (1.2-12 Million Kcal)

Applicable Fuels: Natural Gas, Diesel oil, Light oil, etc.

Applicable Fuels: Natural Gas, Diesel oil, Light oil, etc.

![]()

Application Industries: Petroleum, Chemical, Pharmaceutical,etc.

This boiler adopts a three-pass circular coil structure with conical coils at the ends, effectively protecting the furnace wall at the boiler ends. Equipped with advanced combustion devices, this model features wide fuel adaptability, high energy efficiency, stable performance, and low-pressure high-temperature operation. Its complete automatic control system enables unattended operation.

For more information about this boiler model, please contact us !

Smart Flow Design Innovative variable flow technology ensures smoother thermal oil movement with reduced flow resistance. |

| Maze-type Heat Exchange Structure The boiler's internal spiral coils adopt a three-layer maze layout, doubling the heat exchange area for more thorough heat absorption. |

Waste Heat Recovery Expert Equipped with heat recovery devices at the boiler tail that thoroughly "extract every bit of heat" from exhaust gases, lowering flue gas temperature by over 30℃. |

Quick-access Maintenance Design Features quick-opening doors and inspection ports, making internal examination and maintenance easily accessible. | |

Premium Insulation Kit Using refractory and insulation materials like a "down jacket" for boilers, keeping surface temperature ≤40℃ and safe to touch. |

Green Combustion Technology Incorporates Flue Gas Recirculation (FGR) technology to achieve both high combustion efficiency and NOx emissions meeting local environmental standards. |

| Model | Rated Power (KW) | Rated thermal power (x10⁴ kcal/h) | Design Oil Temperature (≤℃) | Rated Working Pressure (MPa) | Heat Efficiency (≥%) | System Power Supply (KW) | MAX Transport size (m)(L×W×H) |

| YY(Q)W-1400 Y(Q) | 1400 | 120 | 320 | 0.8 | 95 | 35 | 4.3x2.0x2.6 |

| YY(Q)W-1800 Y(Q) | 1800 | 160 | 320 | 0.8 | 95 | 56 | 4.9x2.2x2.6 |

| YY(Q)W-2400 Y(Q) | 2400 | 200 | 320 | 0.8 | 95 | 56 | 5.3x2.5x3.0 |

| YY(Q)W-2800 Y(Q) | 2800 | 240 | 320 | 0.8 | 95 | 66 | 6.1x2.5x3.0 |

| YY(Q)W-3500 Y(Q) | 3500 | 300 | 320 | 0.8 | 95 | 75 | 6.7x2.6x3.0 |

| YY(Q)W-4200Q | 4200 | 360 | 320 | 0.8 | 95 | 95 | 6.9x2.7x3.2 |

| YY(Q)W-4600Q | 4600 | 400 | 320 | 0.8 | 95 | 95 | 7.0x2.9x3.4 |

| YY(Q)W-6000Q | 6000 | 500 | 320 | 0.8 | 95 | 140 | 7.2x3.3x3.9 |

| YY(Q)W-7000Q | 7000 | 600 | 320 | 0.8 | 95 | 140 | 8.0x3.6x4.0 |

| YY(Q)W-8200Q | 8200 | 700 | 320 | 0.8 | 95 | 140 | 8.5x3.7x4.0 |

| YY(Q)W-9400Q | 9400 | 800 | 320 | 1 | 95 | 200 | 9.5x3.8x4.0 |

| YY(Q)W-10500Q | 10500 | 900 | 320 | 1 | 95 | 200 | 10.5x3.8x4.0 |

| YY(Q)W-12000Q | 12000 | 1000 | 320 | 1 | 95 | 240 | 12.4x3.8x4.0 |

| YY(Q)W-14000Q | 14000 | 1200 | 320 | 1 | 95 | 300 | 13.5.x4.0x4.2 |

Leave your email and we’ll send you tailored boiler solutions, case studies, and pricing info within 24h.