Thermal Efficiency:88%-90%

Applicable Fuels: Biomass pellets, straw, wood blocks,etc.

Applicable Fuels: Biomass pellets, straw, wood blocks,etc.

![]()

Application Industries: Heating, Chemical, Food Industries,etc.

Zhejiang XianChuang Energy Technology Co., Ltd. is a leading A-grade licensed boiler manufacturer in China, publicly listed with ASME & CE certifications and 30+ patents. We've delivered one-stop solutions to 200+ premium clients, including Fortune 500 companies and China's top chemical fiber producers.

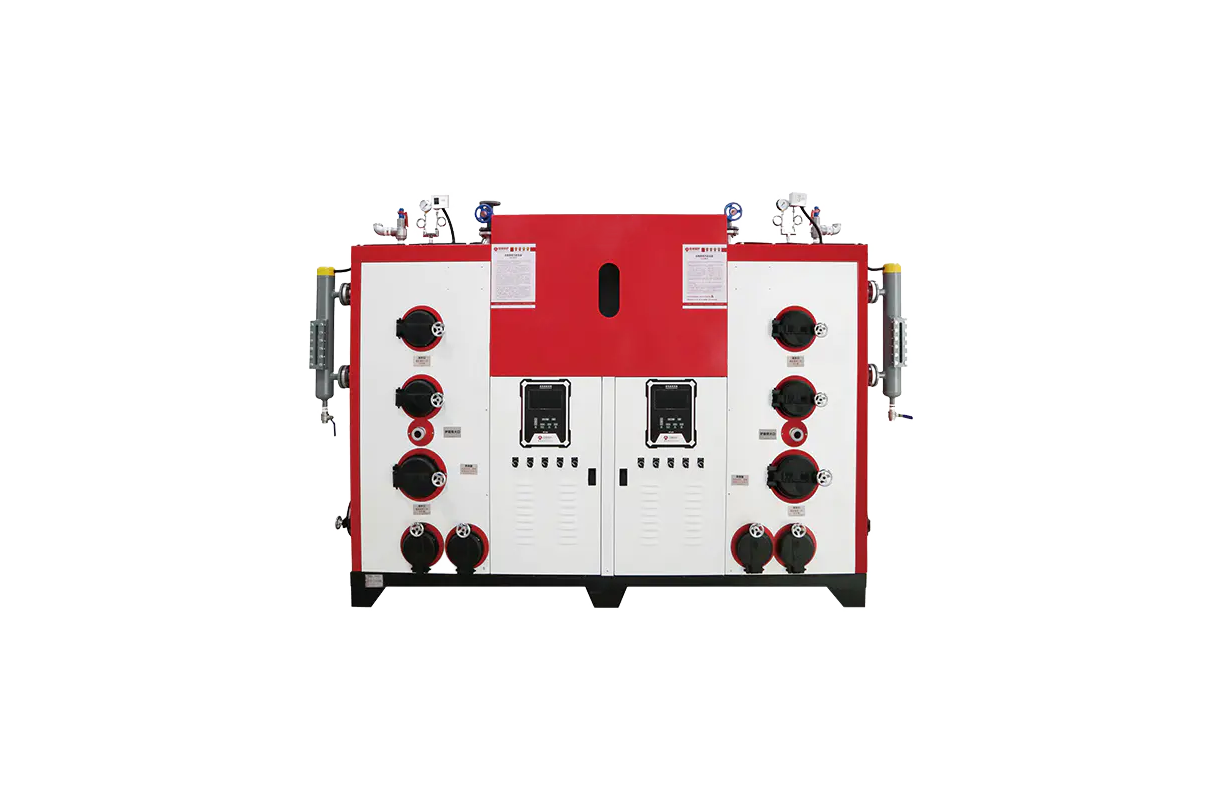

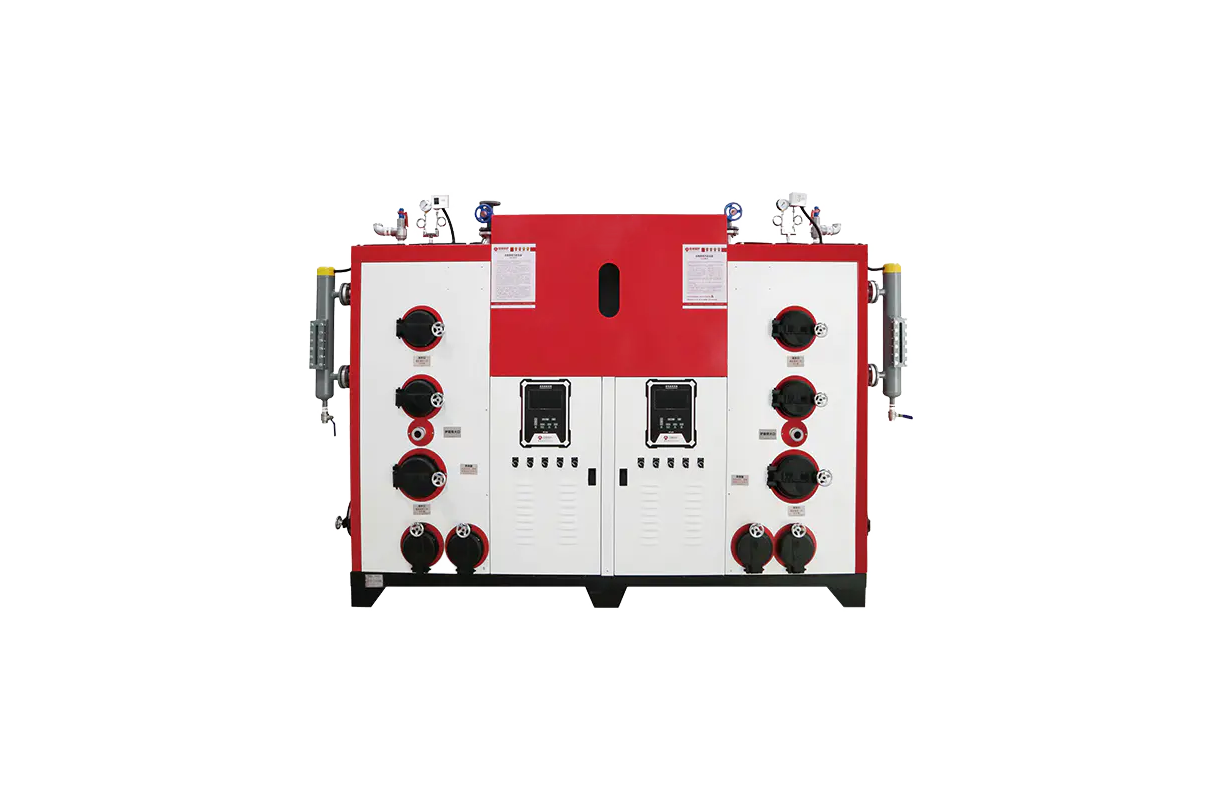

The LHG-s series biomass coal fired steam generator is a semi-gasification fire-tube steam generator that uses biomass pellets as fuel to produce steam. The boiler employs a unique micro-positive pressure combustion technology and is equipped with double economizers and an external water membrane dust remover. It incorporates a secondary air supply for suspended semi-gasification combustion technology, achieving a biomass combustion efficiency of up to 99.9%. The flue gas is recycled through multiple passages, increasing the heating surface area by 30% and significantly enhancing the boiler's thermal efficiency. The biomass steam generator meets environmental requirements in various regions and produces no smoke or dust after normal combustion. The outer shell is constructed with high thermal resistance fibers and an enclosed metal casing as insulation, with careful consideration for ease of operation, maintenance, and repair during the design process.

| Model/Project/Unit | LHG0.1-0.7-S | LHG0.12-0.7-S | LHG0.15-0.7-S | LHG02-0.7-S | LHG025-0.7-S | LHG0.3-0.7-S | LHG0.35-0.7-S | LHG0.5-0.7-S | LHG0.6-0.7-S | LHG0.7-0.7-S | |

Rated evaporation | kg | 100 | 120 | 150 | 200 | 250 | 300 | 350 | 500 | 600 | 700 |

Highest pressure | Mpa | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

Hghest temperature | ℃ | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 |

Boler water volume | L | 26 | 26 | 28 | 28 | 29 | 29 | 29 | 29 | 29 | 29 |

Product size | mm | 1280×950×2500 | 1400×1150×2500 | 1580×1280×2400 | 1500x1300x2100 | 1800×1250×2100 | 1600×1450×2100 | 1650×1500×2200 | 2650×1500×2100 | 2900×1480×2200 | 3200× 1500×2300 |

Bolerwater volume | kg | 600 | 650 | 800 | 880 | 1100 | 1200 | 1300 | 2100 | 2200 | 2400 |

Themal eficiency | % | 88 | 88 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

Full load fuel consumption | kg/h | 16 | 19 | 24 | 32 | 40 | 48 | 56 | 79 | 95 | 110 |

Average fuel consumption | kg/h | 11 | 14 | 17 | 22 | 28 | 33 | 39 | 56 | 67 | 77 |

Hopper capacity | kg | 65 | 72 | 110 | 150 | 160 | 180 | 200 | 330 | 360 | 380 |

Power consumption | kw/h | 0.7 | 0.78 | 0.88 | 0.95 | 1.1 | 1.2 | 1.4 | 2.2 | 2.5 | 3 |

Working pressure | Mpa | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 | 0-0.7 |

Working mode | stand-alone | stand-alone | stand-alone | stand-alone | stand-alone | stand-alone | stand-alone | oombination | combination | combination | |

Leave your email and we’ll send you tailored boiler solutions, case studies, and pricing info within 24h.