Gas, Coal, or Biomass Boilers: Which Fuel Costs Less? Comprehensive Comparative Analysis

In industrial production, boiler fuel costs are a critical factor affecting operational expenses. Among the three common fuel types - gas, coal, and biomass - which offers the most economic advantage? This article provides a detailed comparison from three core dimensions: calorific value, thermal efficiency, and fuel price, combined with practical case studies to deliver scientific cost analysis.

1. Three Core Indicators for Fuel Cost Assessment

To accurately compare fuel costs, understanding these three key metrics is essential:

| Indicator | Gas Boiler | Coal Boiler | Biomass Boiler |

|---|---|---|---|

| Calorific Value Range | 8500-9000 kcal/m³ | 4000-6000 kcal/kg | 3500-4500 kcal/kg |

| Thermal Efficiency | 90%-95% | 60%-80% | 80%-85% |

| Fuel Price Range | $0.4-0.7/m³ | $80-150/ton | $80-120/ton |

Cost Calculation Formula: Hourly Fuel Cost = Required Heat Output ÷ Fuel Calorific Value ÷ Boiler Efficiency × Fuel Unit Price

2. Actual Cost Comparison Analysis (Using 1-ton Steam Boiler as Example)

Assuming 600,000 kcal/hour heat requirement, calculating hourly fuel costs for three boiler types:

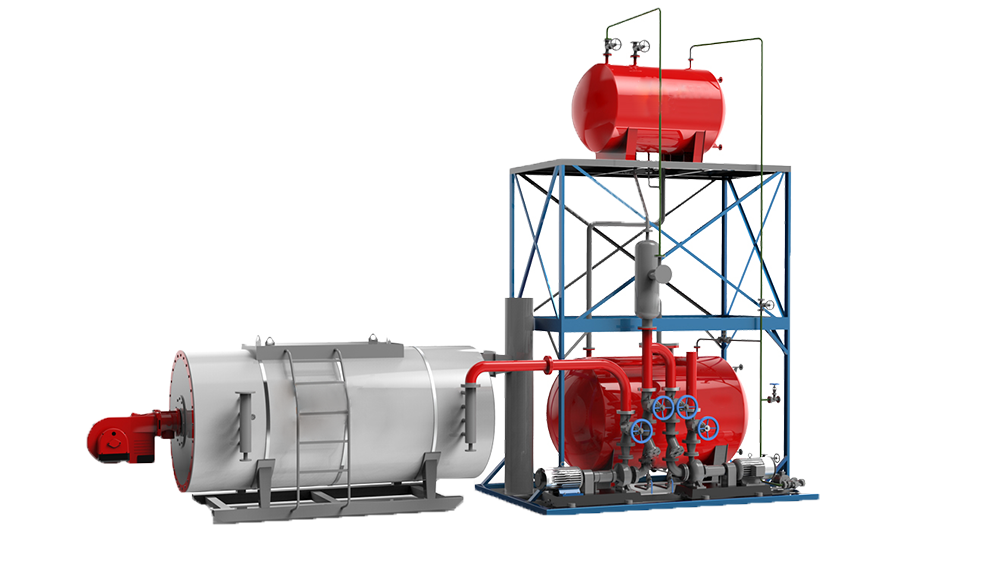

Gas Boiler

Calorific Value: 8600 kcal/m³

Efficiency: 92%

Price: $0.55/m³

Hourly Cost: ≈ $38.5

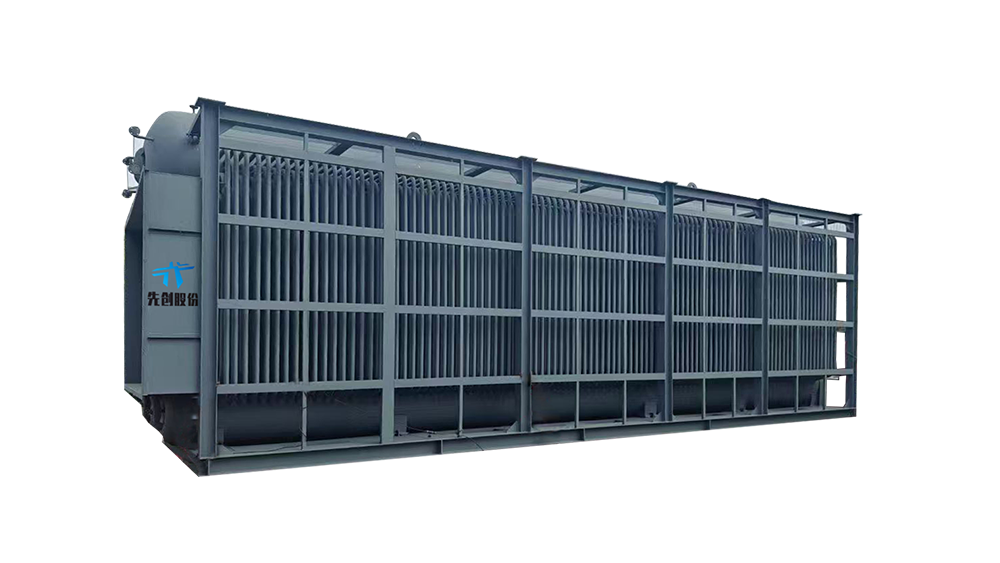

Coal Boiler

Calorific Value: 5200 kcal/kg

Efficiency: 75%

Price: $95/ton

Hourly Cost: ≈ $21.2

Biomass Boiler

Calorific Value: 4200 kcal/kg

Efficiency: 82%

Price: $88/ton

Hourly Cost: ≈ $22.5

Preliminary Conclusion: Based on pure fuel costs: Coal Boiler < Biomass Boiler < Gas Boiler

3. Practical Application Case Studies

Case 1: Vietnam Textile Factory (Coal to Gas Conversion)

Company Profile: Medium-sized textile factory using 6-ton steam boiler

Original Coal Boiler: Annual operation 280 days, 16 hours/day, annual fuel cost ≈ $53,000

Current Gas Boiler: Same operational conditions, annual fuel cost ≈ $101,000

Transition Analysis: Despite 90% increase in fuel costs, automation reduced labor requirements by 2 operators, saving $20,000 annually in labor costs while complying with environmental regulations

Case 2: Thailand Wood Processing Plant (Biomass Selection)

Company Characteristics: Located in agricultural region with abundant biomass resources

Equipment Configuration: 8-ton biomass steam boiler, annual operation 300 days, 12 hours/day

Operational Costs: Local biomass pellets priced competitively at $78/ton, annual fuel cost ≈ $181,000

Comprehensive Benefits: Saves over $80,000 annually compared to gas option, qualifies for renewable energy subsidies

Case 3: Indonesia Palm Oil Processing (Coal Retention)

Special Circumstances: Located near coal mining area with price advantages

Equipment Situation: 15-ton chain grate boiler with completed emission control upgrades

Cost Advantage: Local coal price only $70/ton, annual operation 330 days, 24-hour operation, remains most cost-effective option

Applicable Conditions: Coal remains competitive where policies permit and environmental investments are adequate

4. Other Key Factors Affecting Total Costs

1. Regional Policy Differences

Southeast Asian countries have varying environmental regulations; some promote biomass energy with subsidies; gas boilers advantageous in areas with pipeline infrastructure.

2. Resource Availability Impact

Indonesia, Vietnam have coal price advantages; agricultural regions offer low-cost biomass; gas availability depends on pipeline development.

3. Lifecycle Cost Considerations

Gas boilers have higher automation with lower labor costs; coal boilers require storage space and handling systems; biomass boilers need preprocessing equipment investment.

4. Environmental Compliance Costs

Coal boiler environmental equipment can represent 30%-50% of total investment; biomass boilers require dust removal systems; gas boilers need minimal additional environmental investment.

5. Selection Recommendations and Decision Guide

Based on the above analysis, companies should follow this decision-making pathway when selecting boiler fuel:

Step 1: Assess Policy Environment

Research local environmental regulations, determine if coal boilers are permitted, understand biomass boiler subsidy policies.

Step 2: Analyze Resource Conditions

Investigate local fuel prices and supply stability, calculate actual delivered costs.

Step 3: Calculate Total Cost of Ownership

Consider fuel costs, labor expenses, maintenance fees, environmental investments for 5-10 year lifecycle analysis.

Step 4: Match Enterprise Requirements

Make final selection based on heating characteristics (continuity, stability requirements), site conditions, investment budget.

There is no universally "best" fuel, only the "most suitable" solution for specific conditions. Companies should conduct detailed feasibility analysis before decision-making and consult professional organizations when necessary to maximize investment returns.