Why Economizer Recirculation is a Game-Changer for Industry

In the relentless pursuit of industrial efficiency and environmental responsibility, boiler economizer recirculation has emerged as a cornerstone technology. This system directly addresses two of the biggest challenges in manufacturing and production: high energy costs and carbon emissions. By harnessing what was once wasted heat, plants can unlock substantial operational savings and dramatically reduce their environmental footprint.

Key Benefits and Functional Advantages

1. Enhanced Energy Efficiency and Cost Reduction

The primary function of an economizer is to act as a heat recovery device. It captures residual thermal energy from hot flue gases exiting the boiler and uses it to preheat the incoming feedwater. This process of heat exchange means the boiler itself requires significantly less energy to raise the water to operating temperature, leading to a direct and substantial reduction in fuel consumption. For businesses, this translates to lower operational costs and a stronger bottom line.

2. Reduced Environmental Impact

By improving fuel efficiency, economizer recirculation directly reduces the volume of greenhouse gases and other pollutants emitted per unit of output. Furthermore, it actively lowers the temperature of exhaust flue gases released into the atmosphere, mitigating thermal pollution. This technology is a clear and effective response to the global call for greener, more sustainable industrial practices.

3. Critical Equipment Protection and Longevity

Beyond efficiency, this system plays a vital role in safeguarding boiler infrastructure. During startup or shutdown procedures when feedwater flow may be interrupted, water within the economizer's tubes can stagnate, leading to dangerous overheating and potential tube failure. The recirculation system prevents this by creating a continuous flow path, ensuring water moves through the economizer and protecting it from thermal damage. This extends the equipment's operational lifespan and reduces maintenance and replacement costs.

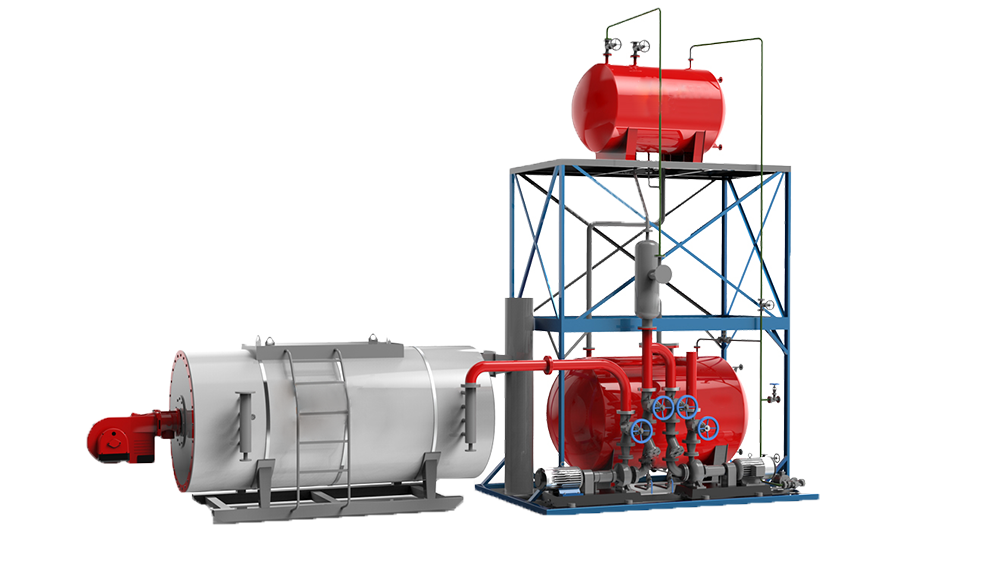

How It Works: The Principle of Economizer Recirculation

The principle revolves around the intelligent recovery and reuse of thermal energy in a continuous cycle:

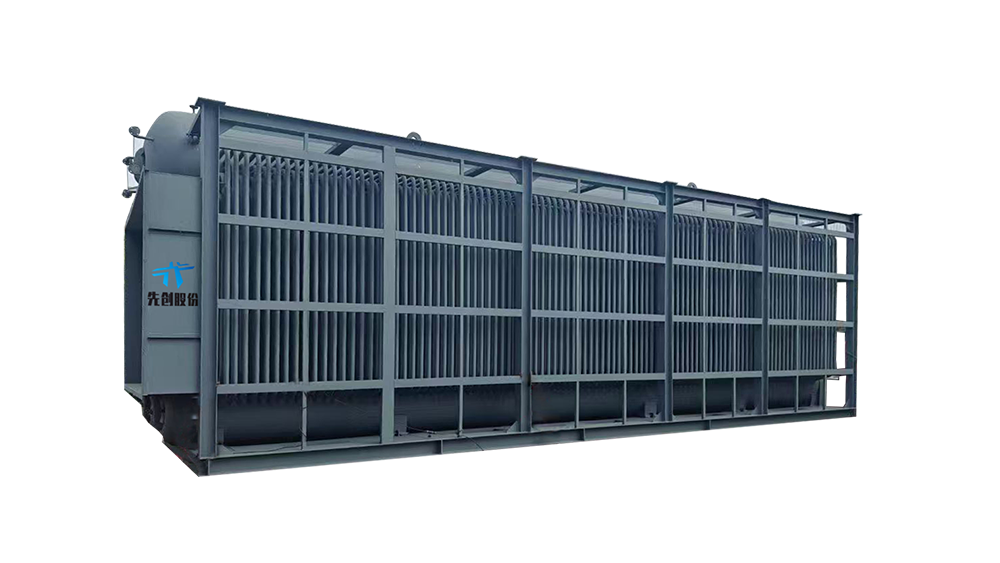

Heat Capture: High-temperature flue gas, which would otherwise be expelled into the atmosphere, is directed through the economizer—a network of pipes or heat exchangers.

Heat Exchange: Inside the economizer, this waste heat is transferred to the cooler feedwater being supplied to the boiler.

Recirculation Loop: To maximize heat extraction, a portion of the now preheated water is recirculated via a dedicated pipe back to the economizer inlet for further heating, ensuring optimal energy capture from the flue gas.

Return to Boiler: The super-heated water is finally fed into the boiler drum, where it requires far less energy to be converted into steam.

This cyclical process ensures that heat is extracted from flue gases as completely as possible, maximizing the overall thermal efficiency of the entire boiler system.

Important Considerations for Implementation

The effectiveness of an economizer recirculation system is not universal. Its performance is influenced by several critical factors, including:

Boiler model and design specifications

Flue gas temperature and flow rate

Feedwater temperature and flow requirements

Therefore, system design and ongoing operation require careful adjustment and optimization tailored to the specific plant conditions to achieve peak results.

Key Takeaways

Economizer recirculation is a proven technology for slashing fuel costs and boosting energy efficiency.

It is a key strategy for industries aiming to reduce carbon emissions and operate more sustainably.

The system provides essential protection for boiler equipment, preventing costly downtime and repairs.

Proper design and tuning are essential to realize the full benefits of the technology.

For forward-thinking industries, investing in and optimizing boiler economizer recirculation is no longer just an option—it is an essential component of efficient, cost-effective, and environmentally conscious operation.